| |

|

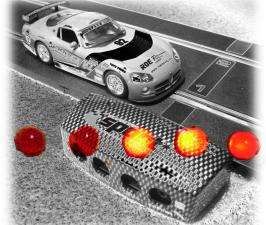

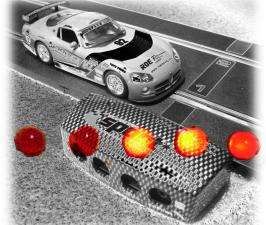

Scalextric Sport

Race Start Controller

Kit484K Supplemental page

|

|

Overview

The original Race Start Controller

project includes a PCB layout for those that wanted to build it

themselves. However the PCB has never been available to buy from Picprojects. In 2010 I designed a new multifunction PCB, and the

original Race Start Controller has been modified slightly to work with

this PCB. The hardware design is essentially the same, the

firmware functionally unchanged, the only modifications to the code

being the I/O since different pins are used to accommodate the design on

the PCB480. You can read more about the PCB480 design

here can read more about the PCB480 design

here

This page provides construction details

for the new PCB and provides information on specific differences. It

connects to the Scalextric throttles in exactly the same way as the

original version and therefore rather than duplicate the information

here you should refer to them main project page for assembly and

connections to your slot car setup. (back to main

page)

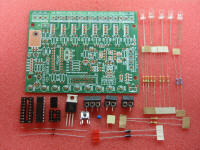

You can buy a self-assembly kit of

parts from the Picprojects eShop

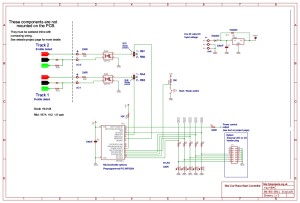

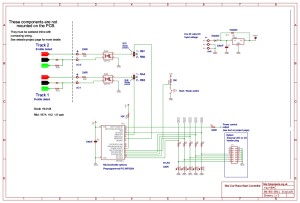

Schematic

This schematic is for the version of

the Race Start Controller assembled using PCB480 and sold as Picprojects

kit #484K.

Download schematic PDF

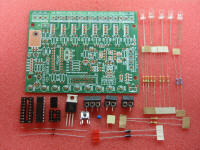

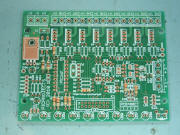

Construction

Construction details are shown below.

You can buy the PCB only or a kit of parts for this project from the

eShop. The kit #484K contains all the components required

to assemble the complete board as shown in the photo guide below,

including a pre-programmed PIC microcontroller.

Click on the photos below for 1024x768 version

|

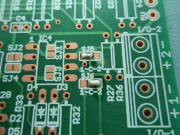

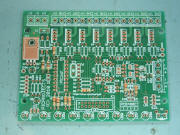

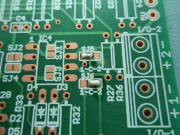

Step 1 |

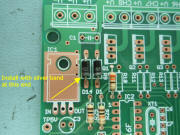

Step 2 |

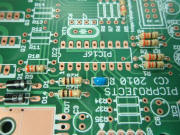

Step 3 |

|

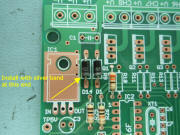

Step 1. Use a blob of

solder to bridge the two solder jumpers as shown. Be sure to

bridge only one half of each jumper.

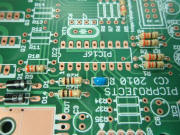

Step 2. Install the

resistor identifying them using the coloured bands. It

doesn't matter which way round the resistors are fitted, the

coloured bands show the value not the orientation.

brown, black, orange, gold - 10K

(R25, R26)

brown, black, orange, gold - 10K

(R25, R26)

orange, orange, brown, gold - 330R (R1,R2,R3,R4,R5,R9,R32,R33)

orange, orange, brown, gold - 330R (R1,R2,R3,R4,R5,R9,R32,R33)

Step 3. Install the

two 1N4003 diodes. Make sure to fit them with the silver band at the

end shown. (this matches the PCB overlay)

|

Step 4 |

Step 5 |

Step 6 |

|

Step 4. Install the 100nF

capacitor C2. Will usually have the number 104 on the body (colour

of part may vary) Step 5.

Fit the 7805 voltage regulator IC

Step 6. Install the two IC

sockets. Note they are indented at one end. Fit the

socket so the indent is at the end arrowed.

|

Step 7 |

Step 8 |

Step 9 |

|

Step 7. Install the 330nF

capacitor C1 Step 8.

Fit the two 2-way terminal blocks together using the dovetail key.

Step 9. Install the switch

and terminal blocks.

If you are using an alternative switch mounted away from the PCB you

may want to omit the switch and solder wires to the switch position

on the PCB. In this case connect to the two smaller holes

within the switch outline of the component overlay.

If you are using an alternative switch mounted away from the PCB you

may want to omit the switch and solder wires to the switch position

on the PCB. In this case connect to the two smaller holes

within the switch outline of the component overlay.

|

Step 10 |

Step 11 |

Step 12 |

|

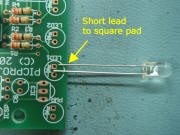

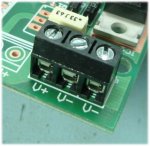

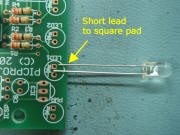

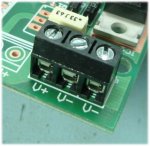

Step 10. Install the

3-way terminal block Step

11. Install the five LEDs into positions LED1 to LED5.

Make sure to identify the short lead and fit it into the hole with

the square pad as shown.

Step 12. You may want to

bend the leads through 90o in which case make sure to bend it so the

short lead will still fit into the hole with the square pad.

|

Step 13 |

Step 14 |

Step 15 |

|

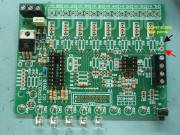

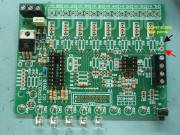

Step 13. Before

proceeding this is a good point to check the PCB for bad solder

joints, solder splashes or bridges and any component lead off-cuts

that may be stuck to the PCB. Having done this apply power to

the board at the 3-way terminal block and use a multimeter to

measure the voltage at the 5 volt test point. (see photo) It should

measure between 4.75 and 5.25 volts, if it doesn't investigate the

cause before continuing.

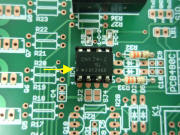

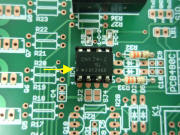

Step 14 / 15. Disconnect the power to the PCB.

Next install the PIC16F628A and CNY74 opto-isolator into their

respective sockets. Make sure to fit the IC's with the indent

in the IC package at the end shown arrowed

|

Step 16 |

Step 17 |

Step 18 |

|

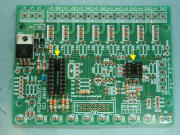

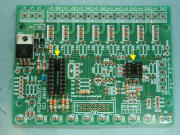

Step 16. With

all the parts fitted, reconnect the power to the PCB through the

3-way terminal block.

You can now test the

board by pressing S1. With no external connections from the

throttles it appears to the firmware that the throttles are closed

so the board with go through a normal start sequence each time S1 is

pressed. If you press and hold S1 it will enter the setup mode

as described on the main page.

Step 17. Since

the PCB used is a multifunction board, the diode and resistor

connecting to the throttles are not accommodated on the PCB.

The photo shows how they should connect between the throttles and the

terminal blocks. Wire tail colours correspond to the diagrams

on the main project page

This is done to

provide a clear illustration of the wiring. It is not

recommended to assemble the resistor and diode without suitable

insulating sleeving. (see Important notes section below)

Step 18. The

original start controller has a connection to operate a 'power

control' output. This output is also available and connects to

the PCB at the point shown by the Orange wire in this photo.

If you're not using the power control output you can ignore this

step.

Important notes

These notes cover

some details important to getting the project working correctly.

Please read

Connecting

power

The power supply to the board connects via the 3-way

terminal block. The PCB is marked V+ and V- indicating the

positive and negative power input. There are two V- connections,

either can be used. The board has reverse

polarity protection so if you accidentally connect it the wrong

way the board shouldn't be damaged.

Connecting LEDs

using the option header K1

Rather than

mounting the five LEDs on the PCB they can be connected via

cables using the optional header. You can buy a 16-way IDC

header socket, plug and cable from the Picprojects eShop under

the 'Components - Connector/Cables' product section

If you use the header to connect the LEDs do not fit LEDs to the

PCB (it's either/or not both)

Power supply

requirements

This version of

the controller needs a smoothed DC power input. The

Scalextric Power Supply supplied with the track does not have an

output smoothing capacitor so isn't directly suitable for use

with this PCB.

If you are building this project in conjunction with the

power

supply project you can use the power from that. If you are

retaining the original Scalextrix Power Supply, this board will

need powering from a separate DC power supply. Since the

board has its own regulator on board any 9-18 volt DC power supply

that is rated for 150mA or greater will work.

Connecting the

throttles

Since the PCB used

is a multifuction board one resistor and diode in each throttle

channel have to be

mounted off the PCB. When I built the original projects I

replaced the 3.5mm jacks on the throttles with 3-pin XLR

plugs and sockets. If you are doing similar the back of

the socket would be a good place to fit the diode and resistor.

You can then run two wires back to the terminal block on the PCB

(with two throttles you will have two pairs of wires going back

to the PCB)

The schematic

diagram on this page uses the same red / black / green

identifiers for the connections to the throttles. You can

therefore refer directly to the main page for additional

information on connecting to the slot car throttles and track.

|

PIC

Firmware

The PIC supplied with the

kit #484K includes a pre-programmed PIC16F628A so you don't need to

download this code or program the PIC yourself. However, should

you need to reprogram the PIC for any reason you can download the

original code here.

The HEX file ready to

program into a 16F628A can be downloaded for free from

here

(right-click Save As).

(a 16F627A can also be used without any modification to the code or

hardware)

|

Description |

Filename |

Download link |

| HEX

file ready to program into the PIC |

480-scs-main.HEX, v1.0.0. 06/02/2011 |

download

download

checksum 0xAFCD |

|