| |

|

Dual

Output PSU

with adjustable voltage

for Scalextric and other slot cars

|

|

Overview

I designed this PSU to use with the

Scalextric Sport slot car racing set my nephews got for Christmas.

Being technically minded when the kids got the set I couldn't help but

have a look at the AC power adapter and how it delivered DC power to the

track. When I stuck my multimeter across the track I discovered that

when two cars were going flat out down the track and one of them crashed,

the voltage delivered to the remaining car increased by as much as 2

volts. The fact that even the

supplied power base is designed to allow connection of separate PSUs to

each track hints that, as is so often the case, it was specified on price

not performance.

I also noticed that my youngest nephew

had trouble controlling the speed of the cars and I figured that if we

could reduce the overall voltage delivered to the track he'd be able to

control the car more easily and keep it on the track longer.

The final piece to this project was the

Race Start Controller (RSC) that I had also been working on. It occurred

to me that with a custom PSU, it should be possible for the RSC to

shut-off power to the track when a car jumps the start.

Finally, if you just want to build the

PSU and don't want to use it with the RSC you can do that too. It will

work just fine on its own.

|

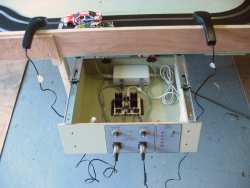

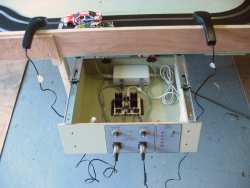

12ft

x 4 ft layout |

Control draw on sliding rails |

Front panel - I've ditched the 3.5mm jacks

for the throttles and replaced them with 3-pin XLR connectors |

Schematics

|

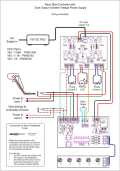

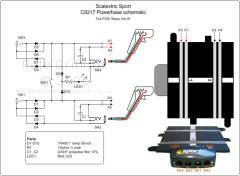

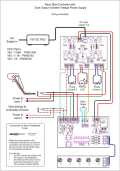

| The

wiring and circuit schematics show how to connect the PSU to the track and

to the Race Start

Controller

The PSU comprises two identical voltage

regulator sections. The schematic only shows one, the second one is

identical and on the PCB component overlay parts names appended with the

letter 'a' refer to the second voltage regulator section.

|

Wiring Schematic

click here for PDF version

|

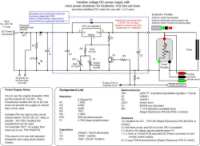

Race Start Controller Schematic

click here for PDF version

|

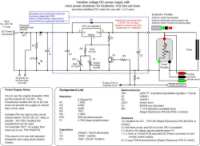

| Circuit

Description

The Dual PSU is built around two LM317T

adjustable voltage regulators. These devices are capable of supplying

a regulated output voltage from 1.25 to 37 volts at up to 1.5amps.

They feature current limit protection and thermal overload protection

so are fairly bullet proof making them ideal for this application.

At the input to the circuit is RF1. This

device is a self-resetting fuse and it is included as a safety

feature. If this fuse trips, the power LED1 will go out. You

will then need to remove the cause of the overload and also remove any

other loads from the PSU before it will reset. In other words don't have a

throttle wide open waiting for the power to come back - it won't.

Diode D1 protects the circuit from

accidental reverse polarity connections to the DC input. Since this circuit

is designed for use with any suitable 18V PSU it is not inconceivable that

some may have a DC plug wired for centre negative. It also protects

any attached PSU from C1 discharging into the input. I've found that

the output from some SMPSU's will dip by a couple of volts when the load

goes from zero to 400mA, a scenario typical of two cars accelerating from a

standstill. Capacitor C1 helps reduce this dip at the input to the

regulators, you may find that you can omit this without any adverse effects.

The components around VR1 follow the basic

LM317 reference designs. Diode D2 prevents damage to the voltage

regulator in the event that the voltage at the output exceeds the input

voltage. Capacitor C2 provides decoupling at the input to the regulator.

The components around the adjust pin of the

regulator set the output voltage. Resistor R4 sets the minimum

output voltage to ~7volts. The preset PR1 in parallel with P1 is used

to set the maximum output voltage. Once PR1 is set, P1 allows the

operator to vary the output voltage between the minimum and preset

maximum.

Transistor Q1 is used to shut-off the

output. Q1 is turned on when the 5 volt signal is applied to the base via

R5 from the 'Power Control In' input. This pulls the adjust input of

VR1 to ground, bypassing the resistor network and causing the output of

VR1 to drop to 1.3volts. In practice this is insufficient for a slot car

motor to actually move the car, particularly from a standstill.

Resistor R5 and R2 pull the base of Q1 low, ensuring that Q1 is turned off

when there is no control input.

Increasing the output current

The LM317K regulator can deliver up to

1.5amps. If you replace RF1, the 1.1amp resettable fuse with a 3 amp rated

part (Rapid Electronics Part No 26-0805 ) and find a 3 amp or greater

rated PSU you can deliver up to 1.5amps to each lane. Diode D1 is only

rated at 3amps so the design is not really suitable for delivering more than

3amps total.

|

|

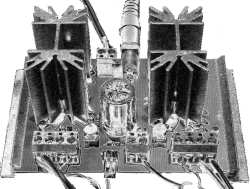

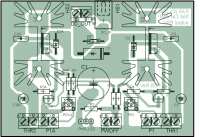

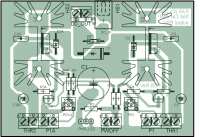

The PCB was designed

using CadSoft Eagle. You can download a free version from their

website http://www.cadsoft.de/

Eagle PCB Artwork file

PCB

artwork in PDF format

On the component

overlay, component names with an 'a' appended are the duplicated parts

of the schematic for the second PSU.

If you use the artwork

from the PDF to make the PCB, check that the output is to scale.

Overall board dimensions are 2.7" x 3.85".

|

PCB Component Overlay

|

DC

Input Power Supply I

deliberately chose not to build a transformer based power supply for the

input to this circuit for the following reasons

-

It

avoids having AC mains voltages present and all the safety issues that

involves.

-

For

the cost of the transformer and associated components you can buy a

suitable Switch Mode PSU.

-

Switch

Mode PSUs are more efficient and generally have over voltage,

short-circuit and thermal protection designed in.

For

these reasons I chose to use a switch mode PSU to use as the input to this

circuit. One reason not mentioned above is that in my work I have

access to assorted redundant SMPSUs. The one I've used on the final

version of this is an 18volt 1.1amp PSU from an HP Scanner. I've tried

a 22volt 2amp PSU I bought on E-bay for £6 which also worked

fine.

You

need a PSU that can supply at least 1 amp, a bit more won't hurt but it

won't make your cars go any faster either. You need to supply the

circuit with at least 4 volts more than the maximum output at the

track. In theory you could get away with a 16volt input but I

recommend 18volts. You also need to make sure that it will work

without any load, most of the power-brick type SMPSUs will, but make sure

the one you buy does.

A

good place to look is CPC at www.cpc.co.uk.

I found the following, all of which appear to be suitable (though I

haven't tried them)

18V / 1.66A - part #

PW01446

18V / 1.1A - part # PW00752

18V / 1A - part # PW00526

Circuit construction

and setup

When constructing the circuit on the

PCB, don't be tempted to install the big components first, they make

it difficult to install the small parts afterwards.

-

Install

RF1, resistors, preset, diodes and capacitors except C1 and solder

to the PCB

-

Next

install the DC power connector and PCB screw terminal blocks

-

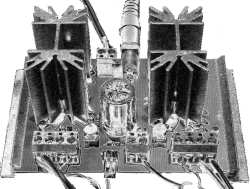

Now fit

both heat sinks and solder the lugs to the PCB.

-

With the heat sinks

fitted install the voltage regulator IC's. You might want to

apply a bit of heat sink compound to the back of the

regulator. Push the legs through the PCB holes but don't

solder them in place at this stage. Using an M3 screw and

nut attach the regulator to the heat sink. Tighten the

screw being careful not to twist the regulator. A tip here is to

ensure that the screw is fitted so that it is facing the edge of

the PCB otherwise you can't get a screw driver on it

When

the voltage regulator is bolted to the heat sink, the heat sink is

electrically connected to the regulator output. It is important

that the heat sinks do not touch any other components or metal

work inside an enclosure.

-

Once the

regulators are attached to the heat sink, solder them to the PCB

and then fit capacitor C1

-

With all

the components fitted, have a good look at the track side of the

PCB to ensure there are no solder bridges and all the joints are

sound.

Once you're

happy with the assembly of the board connect a suitable DC power

supply to the DC input.

-

Measure

the voltage at the DC_out connector on the PCB. This should be the

same as the rated output of the DC power supply.

-

Now

measure the voltage at the THR1 and THR2 connectors. The

voltage should be somewhere between 7 and 16 volts. If you adjust

preset PR1 / PR1A you should see the output voltage change.

-

Next

attach the potentiometers P1 / P1A to the terminal

connectors on the PCB.

-

Adjust

preset PR1 to its mid position.

-

While

measuring the output voltage at the THR1 terminal adjust P1 fully

clockwise then fully counter clockwise. Measure the voltage

at the THR1 connector in both positions, then leave P1 set at the

position where the measured voltage was highest.

-

Now adjust

preset PR1 until the voltage measured at the THR1 connector is 12.5

volts.

(You can adjust the maximum output up to about 14 volts which will

make the cars go faster - however you do so at your own risk - if

you burn the cars motor out or damage it in any other way it was

your choice)

-

Repeat the

last three steps with THR2/P1A/PR1A to setup the maximum output on

the second PSU.

The circuit is now complete and ready

to connect up as shown in the wiring schematic above

Notes for use with the Race

Start Controller

|

|

Don't follow my wiring colours here,

I hooked this up before I did the schematics

|

|

|

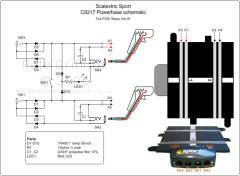

| A schematic

diagram of the internals of the Sport Powerbase track part

C8217.

If you want to connect the

PSU to the track via the Powerbase, rather than wiring

directly to the underside of the track you can. Details

of how to do this are shown on the Wiring Schematic above.

If you do this you must

ensure that the Switch is set for dual PSU and you don't

connect anything to the 16V inputs on the Powerbase.

|

|

|

| |

PDF version |

|

|

Parts

Listing

-

All

Rapid parts/descriptions correct at 19-Sept-2008. You should

check part# and descriptions are correct when ordering in case

I've made a mistake transferring them onto this page.

-

The

resistors are sold by Rapid in packs of 100. You may find it

cheaper to buy some or all of the parts from other sources - I make no

recommendation.

-

You will also needs some short

lengths of wire for the interconnections between the PCB, potentiometers. Rapid sell a pack of 11 colours x 2M lengths of stranded

equipment wire, Part # 01-0108

|

| Qty |

Part Number |

Description |

| 1 |

55-0120 |

5mm green LED |

| 2 |

47-3318 |

LM317T voltage regulator |

| 2 |

47-3130 |

1N4001 diode |

| 1 |

47-3144 |

1N5401 diode |

| 2 |

81-0066 |

BC548B |

| 1 |

26-0780 or 26-0740 |

1.1A polyswitch fuse |

| 2 |

67-0608 |

2K, 6mm cermet preset

potentiometer |

| 2 |

65-0710 |

4.7K, 16mm potentiometer |

| 2 (sold in packs of 100,

order Qty 1) |

62-0382 |

3.3K ohm 0.25 watt resistor |

| 1 (sold in packs of 100,

order Qty 1) |

62-0374 |

1.5K ohm 0.25 watt resistor |

| 1 (sold in packs of 100,

order Qty 1) |

62-0410 |

47K ohm 0.25 watt resistor |

| 2 (sold in packs of 100,

order Qty 1) |

62-0354 |

220 ohm 0.25 watt resistor |

| 2 (sold in packs of 100,

order Qty 1) |

62-0370 |

1K ohm 0.25 watt resistor |

| 2 |

11-1046 |

10uF / 25volt Tantalum

Capacitor |

| 1 |

11-0765 |

2200uF / 35volt Radial

Electrolytic |

| 2 |

08-0235 |

100nF disc ceramic

capacitor |

| 6 |

21-0440 |

2-way, 16A interlocking

terminal |

| 2 |

36-0316 |

TO-220 heatsink, 3.9oC/Watt |

| 1 (to suit DC

power supply) |

20-0962 |

2.5mm PCB mount DC power

socket |

| 20-0960 |

2.1mm PCB mount DC power

socket |

|