|

F1 Gantry Race Start Lights Controller

How to modify the timing data

The timing data and mode parameters are

stored in the EEPROM data memory of the PIC microcontroller. This can be

edited and reprogrammed by the end-user to customise the parameters to

suit a specific application.

You will need a PIC programmer to read

and reprogram the PIC16F684 microcontroller. I recommend the

Microchip PICkit2 using the stand-alone application software. This

has been used in the guide shown below.

Important:

Important:

Since the PIC microcontroller used

in the F1 Gantry Race Start Lights project has the Program Memory code protected it

is important that you DO NOT write the program memory area when writing

data back to the EEPROM.

By default it will overwrite the program memory unless you uncheck the

Program Memory Enabled option.

Step 1

Remove the PIC microcontroller from the

control board and place in the PICkit2 programming adapter, (

if you don't have one see here for details of

how to make one)

Step 2

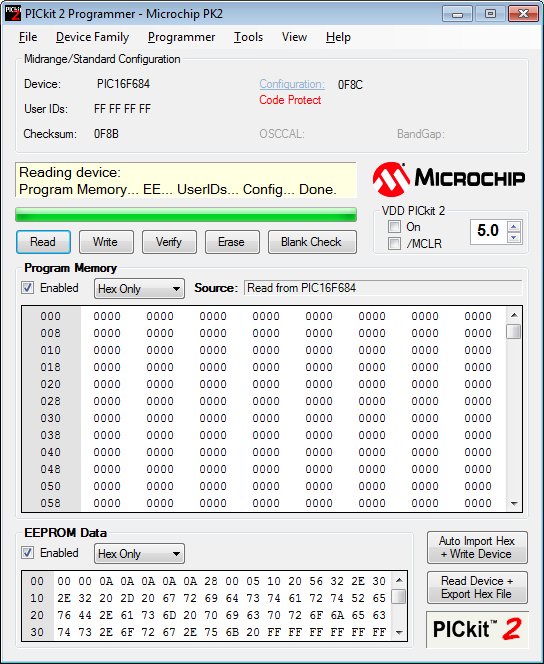

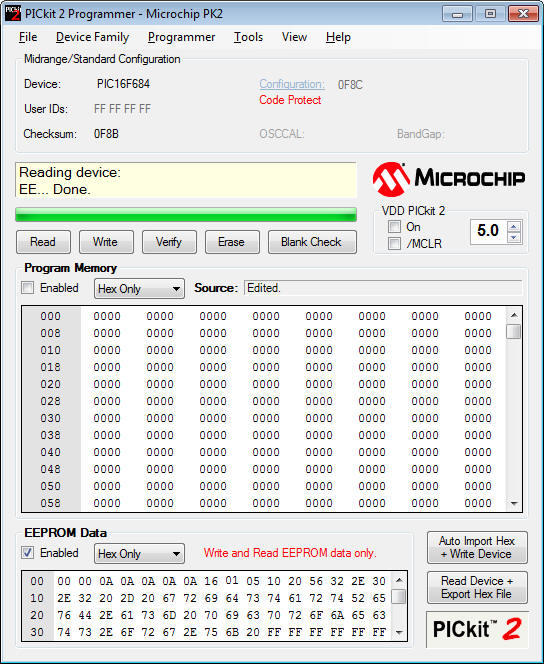

Click on the 'Read' button. When

it has finished reading the PIC you should see something similar to the

screen-dump below.

Note that:

- Device is a PIC16F684

- 'Code Protect' is shown in red

- The Program Memory contains all

'0000'

- Source shows 'Read from

PIC16F684' so we know the data has been read out of the PIC

- 'Program Memory' check box

is Enabled - This should be unchecked before writing back to the

PIC.

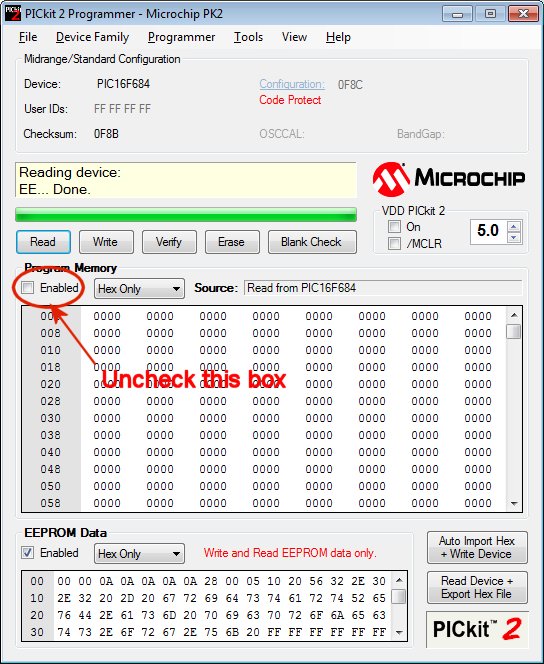

Step 3

Uncheck 'Program Memory' enabled check

box.

It is important that this is disabled

otherwise when the modified EEPROM data is written back, it will erase

the Program Memory area. If this happens, you will need to return

the PIC to us for reprogramming as it will no longer work.

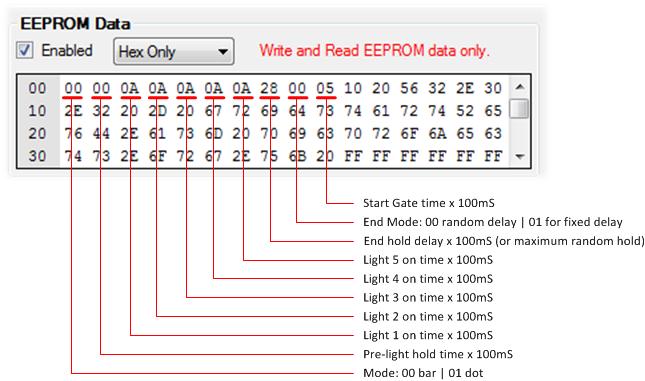

Step 4

You can now edit the data in the EEPROM

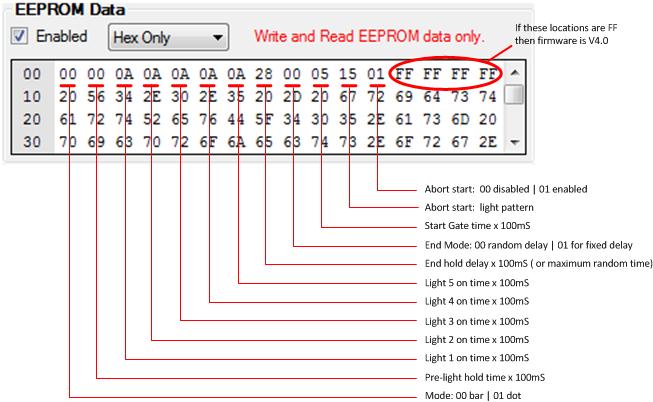

Data window. From August 15th 2012 kits ship with V4. firmware

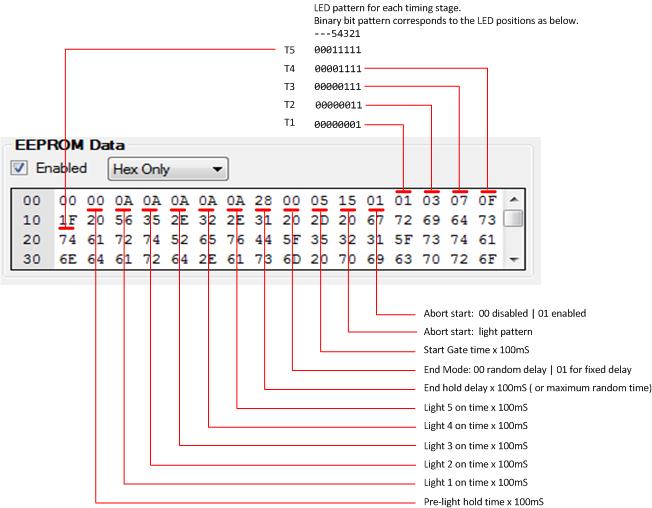

- The parameters that can be changed

are shown below. An example of edited timing data is show in

the next step.

- The values entered in the EEPROM

Data window must be in hexadecimal. (see Decimal /

Hexadecimal Numbers section below if you don't know what this means)

- If you mess up at this point you

can go back to Step 2 and read the EEPROM again to clear any

changes you have made.

Firmware V3. EEPROM example

Firmware V4. EEPROM example

Firmware V5. EEPROM example

Decimal / Hexadecimal Numbers

Decimal / Hexadecimal Numbers

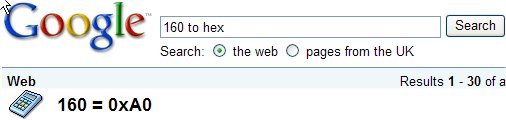

If you don't understand

hexadecimal, use Google to do the conversion for you. In the

example below we want to convert 160 to a hexadecimal. The

result is shown as 0xA0. You ignore the 0x part and use the

last two digits for the EEPROM Data, in this example it would be A0

The largest decimal number that

can be used in the timing data is decimal 255 (hexadecimal FF)

Parameters that can be modified

The table below is copied from the main

project page for continuty.

Modes and

Timing

|

Display modes

The outputs can operate in

either bar or dot mode. |

|

| Timing Data

The timing diagram shows

all the parameters that can be configured. These can

be set from 0 to 25.5 seconds in 100mS intervals

Default timings shown as

decimal and (hex)

supplied in the kit.

0 (00)

; light mode value, 00 bar | 01 dot

0 (00) ; pre-light hold time value x 100mS [TP]

10 (0A) ; light 1 on time value x 100mS [TL1]

10 (0A) ; light 2 on time value x 100mS [TL2]

10 (0A) ; light 3 on time value x 100mS [TL3]

10 (0A) ; light 4 on time value x 100mS [TL4]

10 (0A) ; light 5 on time value x 100mS [TL5]

40 (28) ; end hold delay value x 100mS (or maximum random time) [TH]

0 (00) ; end mode: 0 for random end delay | 01 for

fixed end delay

5 (05) ; start gate output time value x 100mS [TSTC]

This gives 5 lights

illuminating in bar mode at 1 second intervals with a 0-4

second random delay at the end. Start gate output is

active for 0.5S |

|

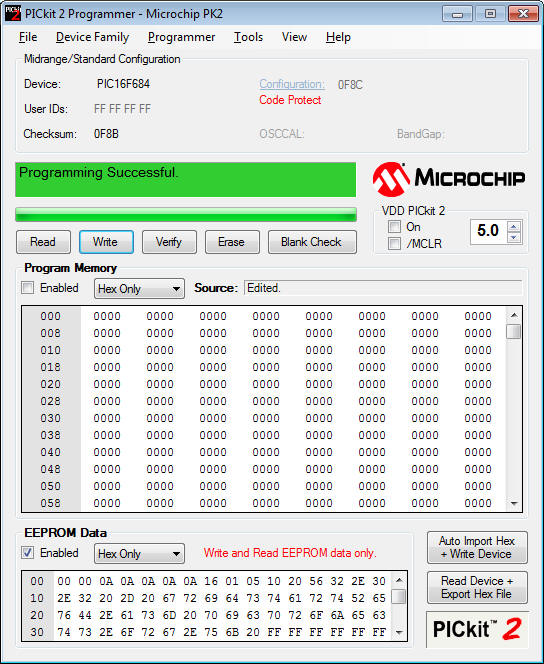

Step 5

The screen shot below shows the EEPROM

Data with two values changed. This is an example and you can of

course edit all the timing parameters to suit your application.

- the 'End hold delay' value from 28

to 16.

16 equals 22 in decimal so the end hold value is now 22 x 100mS =

2.2S

- the 'End hold mode' value from 00

to 01.

This changes the mode from a random end delay to a fixed delay; in

this case it will be 2.2 seconds since we also changed the 'End hold

delay' value.

Note that:

- Source is showing as 'Edited'

This is because the EEPROM data has been changed from that read back

from the PIC in Step 2.

- In the EEPROM Data section it

shows 'Write and Read EEPROM data only'.

This is showing because 'Program Memory enabled' has been

unchecked.

Step 6

When you have edited the EEPROM data to

suit your application you can reprogram the PIC by selecting the Write

button.

Make sure that the 'Program Memory enabled' check box is UNCHECKED before

clicking on the Write button - hopefully you're getting the message :-)

Make sure that the 'Program Memory enabled' check box is UNCHECKED before

clicking on the Write button - hopefully you're getting the message :-)

Once the PIC has been reprogrammed it

can be installed back in the control PCB and tested.

Contact us:

|