|

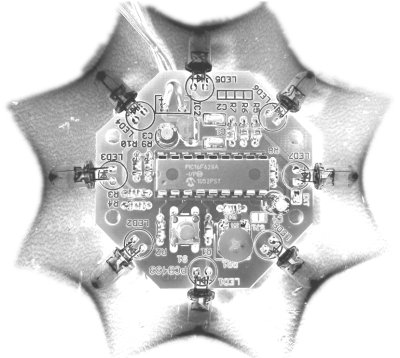

UFO

round LED Chaser

with speed control

for PIC16F628A (#433K)

|

|

Description

This is an updated version of

the UFO LED Chaser project, revised to use the PWM LED Chaser

code version 3.0.0 with support for variable chase speed.

The basic LED chaser 'engine' firmware is the same as that used with the 481/483 LED

chaser projects also on this site. The only difference is the

sequence data used to create the programmer ready .HEX file.

This has

been modified to include chase effects that suit the circular

arrangement of LEDs.

Unlike many simple LED chaser

projects the design presented here provides 8 LEDs

directly driven from the PIC along with a single mode control switch

and speed adjust control. The

firmware elsewhere on this page drives the LEDs with a

5 bit PWM signal providing each of the 8 LED channels with four

levels of intensity; off, dim, mid and bright.

A number of sequences are programmed into the firmware to

provide some interesting visual effects and chase sequences.

The software has sequential, random and manual sequence run

modes and manual advance to the next sequence in any mode.

The selected sequence and mode are also saved to non-volatile

memory so it will always restart in the selected mode.

The design is deliberately

simple with each LED being directly driven from a PIC I/O pin.

You can use it with different

sized LEDs and mixed colours. While it works well as a

simple LED chaser, thinking outside the box it can be used to add

effects to toys and models and even accessorize fancy dress

costumes. See FAQ

A solder pad jumper on the PCB

selects between fixed speed chaser using internal timing or

variable chase speed adjustable using the on-board variable

resistor. The adjustable chase speed option makes it

ideal for use in a wide range of applications. The kit

433K includes all parts needed to build the variable speed

chaser.

The firmware pre-programmed

into the PIC16F628A supplied with the kit includes over 34 chase

effects and sequences. If you're interested in PIC

micros and programming and want to modify the sequences or

create new ones, the source code and

programmer ready HEX file is provided at the bottom of this page.

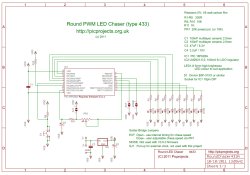

Schematic

Download

schematic in PDF

Circuit Description

The heart of the LED chaser is

the PIC 16F628A microcontroller, IC1. The program that runs on this chip controls the LEDs

attached to the output port pins. Resistors R1 thru R8

limit the current through LED1 - LED8 to a safe level that

won't damage the PICs I/O ports or LEDs. Resistor R9

provides a pull-up for the input connected to switch S1.

R10 holds the PICs MCLR reset signal high.

The variable resistor PR1 along

with C4 are used to create a software oscillator. C4 is

charged and discharged via PR1 from port B0 output. The

input on Port A7 is monitored by the firmware, when the input

goes high port B0 is driven low to discharge C4. When Port A7

goes low, port B0 is driven high to charge C4. An

important requirement is the use of a Schmitt trigger input

buffer on Port A7 input pin which provides the

necessary hysteresis to make the software oscillator work.

This oscillator is then used to provide the clock for the chaser

timing and since the speed is controlled by the rate C4 charges

through PR1 the chaser speed can be controlled by adjusting

PR1. A 1K0 resistor, R11 is placed in series with PR1 to set the

maximum chase speed when PR1 is adjusted to minimum resistance.

Capacitor C1 is used to

decouple the 5 volt power supply to the PIC. If you're building the

circuit on a breadboard or stripboard you should ensure it is

located close to the PICs Vdd connection (pin 14 ).

Power is supplied to the

circuit via the +/- solder points. The voltage regulator,

IC2 is a LM2931-5.0, low-drop-out regulator and will maintain

regulation with an input voltage down to 5.8 volts. Input

voltage for the LED chaser should be between 6 volts and 14

volts to ensure power dissipation remains within limits.

The LM2931-5.0 regulator is designed for battery powered and

automotive applications and includes internal current limiting,

thermal shutdown, as well as reverse battery connection without damage to

itself or the circuit behind it. Capacitor C3 is important

and must be fitted to prevent instability of the regulator

output

Typical current drawn by the

circuit with all LEDs on is only around 80mA; with all LEDs off

it is under 5mA.

Notes:

- The latest

high brightness LEDs are very bright even with 330R current

limiting resistors. However, if you do need to change these resistors

for some reason take into account the maximum current

that the on-board voltage regulator can deliver is 100mA.

- EXT solder bridge

jumper.

When left open the chaser runs at a fixed speed using the

internal sequence timing data.

When closed (bridged with solder on the PCB) the chaser uses the software controlled

oscillator for timing, the frequency is adjusted using PR1

which in turn controls the chase speed.

If you leave the 'EXT' jumper open, you can omit PR1,

R11 and C4. The circuit and firmware will operate

correctly using the internal timing data.

- The jumpers marked 'SJ1'

and 'MODE' are not currently used. Do not

bridge them with solder.

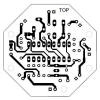

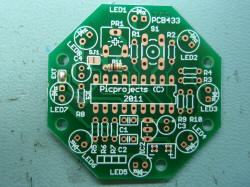

PCB Layout

The PCB measures 48mm across the

flat faces

Four mounting holes are 3mm

diameter (use M3 screw)

Artwork for this board is not

available since the double sided layout isn't really suitable

for home production.

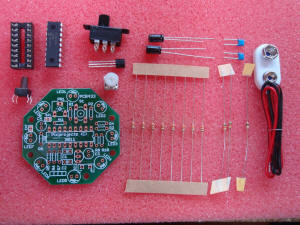

Component List

| Although

we're no longer selling the kit for this project we

still have stock of the PCB433 available.

Cost is £10 for 10 PCBs +

postage (we ship world wide)

email

pcb433@picprojects.biz if you're interested in buying.

Kit

Component list

| Label |

Description |

Qty |

| R1-R8 |

330R 5%,

0.125 watt carbon film |

8 |

| R9, R10 |

10K 5%,

0.125 watt carbon film |

2 |

| R11 |

1K0 5%,

0.125 watt carbon film |

1 |

| PR1 |

20K preset |

1 |

| C1,C2 |

100nF

multilayer ceramic (2.5mm) |

2 |

| C3 |

47uF

radial electrolytic |

1 |

| C4 |

2.2uF

radial electrolytic |

1 |

| IC1 |

PIC16F628A

(pre-programmed with firmware) |

1 |

| IC2 |

LM2931-5.0

LDO regulator |

1 |

| SW1 |

Tactile

switch (like Omron B3F-31xx) |

1 |

| SW2 |

sub-minature slide switch |

1 |

| C1 |

battery

connector + 150mm leads |

1 |

| SKT1 |

18 pin DIP

socket |

1 |

|

PCB433 |

Double

sided FR4, thru-plated, with solder mask, top overlay

and OSP finish. |

1 |

- Kit #433K does not

include the LEDs, these can be bought separately or

sourced independently.

- Kit #433KBL

includes 8 x 5mm high brightness blue LEDs

- The PCB is available to

buy on its own if you want to source the parts

and program the PIC yourself. (programmer ready

HEX file is free to download here)

|

Kit 433K

PCB Only (433P) |

| |

|

Construction notes:

- Follow

these instructions carefully.

- The PCB is

double sided, thru-plated which makes removal of incorrectly

installed components difficult without damaging the component

and/or the PCB.

- Pay attention to the

assembly instructions and make sure each component is fitted the

right way round and in the right position.

- Some

components need to be fitted the correct way round and

others look similar but have different values so must be

identified and fitted in the correct position.

- Check

twice, solder once :-)

click on the photo's for

1024x768 large version.

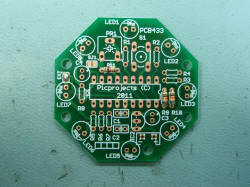

Fig.1 |

Fig .2 |

Fig. 3

|

|

Fig 1. Start by bridging the solder jumper marked 'EXT' with a blob of

solder

Next

fit the resistors. There are 11 in total: 8 x

330R resistors, 2 x 10K resistors and 1 x 1K resistor.

The colour bands only

indicate the resistance value. Since resistors are

not electrically directional components it doesn't

matter which way round the resistor is fitted.

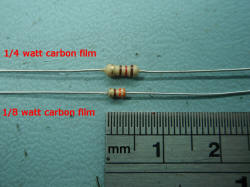

The resistors used here are 1/8 (0.125) watt parts which are about half the

size of standard 1/4 (0.25) watt resistors so the colour bands

are not so easy to see. If you buy the PCB only and are

supplying your own parts make sure to get 1/8 watt

resistors as the 1/4 watt ones are too big to fit on the

PCB.

The resistors used here are 1/8 (0.125) watt parts which are about half the

size of standard 1/4 (0.25) watt resistors so the colour bands

are not so easy to see. If you buy the PCB only and are

supplying your own parts make sure to get 1/8 watt

resistors as the 1/4 watt ones are too big to fit on the

PCB.

In Fig 2.

Fit the single 1K0 resistor to position R11

[brown-black-red-gold]

[brown-black-red-gold]

In Fig 3.

Next fit the two 10K resistors to positions R9 and R10

[brown-black-orange-gold]

[brown-black-orange-gold]

|

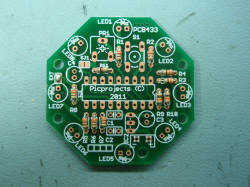

Fig.4 |

Fig.5 |

Fig.6

|

|

Fig 4. Finally

fit the eight 330R resistors to positions R1 to R8

[orange-orange-brown-gold]

[orange-orange-brown-gold]

Resistor colour codes explained

Fig 5.

Next

fit the two 100nF capacitors C1 and C2. These are marked '104' on one side

(see photo right)

The package on these is

blue, it has no significance and may be any colour.

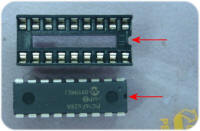

Fig 6. Fit

the 18 pin DIL socket to position IC1. You will see a small notch in

one end. It should be fitted so the notch is at

the same end as the small semi-circle marking on the PCB

overlay. Do not install the PIC16F628A into the socket

at this stage.

|

|

Fig.7 |

Fig.8 |

Fig.9

|

|

Fig 7. Next fit

IC2 (LM2931 LDO voltage regulator). This has three

leads and must be fitted the correct way round.

The body has a 'D' shaped profile when viewed from above

and it should be fitted so it matches the marking on the

PCB overlay

Fig 8. The two

electrolytic capacitors look very similar but have

different capacitance values so you will need

to inspect them to identify which one is which:

- C3 is marked 47µF

- C4 is marked 2.2µF

Fig 9. Capacitors C3 and C4

must be fitted the correct way round. You will see

that one of the leads is shorter. This is the negative terminal

of the capacitor. It must be located so the short

lead is in the hole towards the bottom edge of the PCB

as shown Fig 9. photo.

It is important that the correct value capacitor is

fitted in each location or the circuit will not operate

correctly.

It is important that the correct value capacitor is

fitted in each location or the circuit will not operate

correctly.

|

Fig.10 |

Fig.11 |

Fig.12 |

|

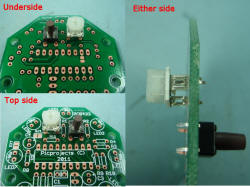

Fig 10. You now need

to fit the switch S1 and speed control resistor PR1. For

the construction notes I've mounted them both on the

component side, however these can be fitted to

either the

component side or the

solder side of the PCB. Which side you fit the

switch and resistor will depend on how you are going to

use the LED chaser and mount the

assembled board. The photo in Fig 10.

illustrates the different ways they can be fitted.

The leads on the switch are a tight fit. Position

the ends of the leads into the holes in the PCB, then

push with even pressure using the tips of your thumbs on

either side of the switch body. It should then snap into

place. Don't try and push it into place using the

button.

The leads on the switch are a tight fit. Position

the ends of the leads into the holes in the PCB, then

push with even pressure using the tips of your thumbs on

either side of the switch body. It should then snap into

place. Don't try and push it into place using the

button.

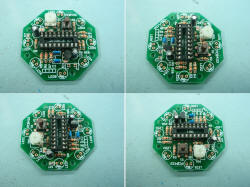

Fig 11. This photo shows the assembled board

from four different views. Your board should now

have all the components shown here assembled onto the

board.

Fig 12. The switch in-line with the battery

connector is used as a power on/off switch.

Take the battery lead and the slide

switch. Cut the red wire about half way along its

length. Strip back about 7mm of

insulation from each end. Insert the bare wire

ends half way through the hole in the switch terminal

and bend back 180o. Now solder to the

terminal as shown in the photo.

The switch is a DPDT (double-pole, double-throw) type

with 6 terminals. Only two are connected for the on/off

switch function.

|

Fig.13 |

Fig.14 |

Fig.15 |

Fig 13. Solder

the battery connection lead to the solder points as

shown. There is a hole in the PCB; pass the

leads through this hole then insert into

the solder points (red to +, black to -). This

hole provides strain relief for

the wires.Fig 14.

[You

don't have to do this step if you don't have access to a

voltmeter, but it's worth doing if you can]

Check the underside of

the board to make sure the solder joints are good and

there are no shorts or solder bridges, resolder any

suspect joints and clean off the underside.

Apply

power to the board; the input voltage (at the battery

terminals) should be between 6 and 14 volts DC. A 9 volt

PP3 battery is ideal for this.

Measure the voltage

between pins

5 and 14 of the IC1 socket. IC2 regulates the

input voltage to a nominal 5 volts so it should measure

between 4.8 and 5.2 volts. If it doesn't

investigate why and correct the problem before

continuing with assembly.

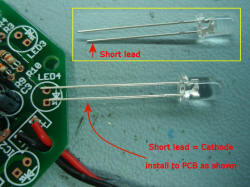

Fig 15. You

can now solder the LEDs into position.

The LEDs must be installed the correct way round.

Each LED has two leads

and one lead will be shorter than the other. The short

lead normally indicates the LED Cathode terminal and

it must be fitted into the hole toward the arrow point

on the PCB overlay.

I have yet to see an LED where the short lead is not the

Cathode, however with so many suppliers of cheap LEDs

from China and South East Asia it is worth checking an

LED out-of-circuit before assembling them onto the PCB.

I have yet to see an LED where the short lead is not the

Cathode, however with so many suppliers of cheap LEDs

from China and South East Asia it is worth checking an

LED out-of-circuit before assembling them onto the PCB.

The

basic 433K kit is supplied without LEDs so

you will need to supply these yourself, or you can buy

them from the picprojects eShop. Kit 433KBL, also

available from the eShop includes 8 x 5mm high

brightness blue LEDs. The

basic 433K kit is supplied without LEDs so

you will need to supply these yourself, or you can buy

them from the picprojects eShop. Kit 433KBL, also

available from the eShop includes 8 x 5mm high

brightness blue LEDs. |

Fig.16 |

Fig.17 |

Fig.18 |

|

Fig

16. When soldering the LEDs to the PCB solder only

one lead of each LED to start with. Once all the

LEDs are fitted, adjust their position so they are

correctly aligned and pointing in the direction

required. Then solder the remaining leads to fix

the LED and complete the electrical connection.

If you solder both leads of each LED and then try and

move it you risk damage to the PCB and/or LED.

If you solder both leads of each LED and then try and

move it you risk damage to the PCB and/or LED.

Fig

17. This

photo show the completed LED chaser. The LEDs

have been bent at a right angle to change the visual

effect of the chaser. The LEDs can also be mounted

vertically or even using short flexible wire fly-leads

if you are building it into a custom application.

Fig

18. Finally you can fit IC1, the PIC 16F628A

microcontroller. The PIC has a notch in one end of

the device and assuming you have fitted the socket

correctly, the PIC should be inserted into the socket

with the notch in the PIC at the same end.

Referring back to Fig 18. the notch should be at the

right hand end as seen in the photo. Fig

18. Finally you can fit IC1, the PIC 16F628A

microcontroller. The PIC has a notch in one end of

the device and assuming you have fitted the socket

correctly, the PIC should be inserted into the socket

with the notch in the PIC at the same end.

Referring back to Fig 18. the notch should be at the

right hand end as seen in the photo.

Make sure the pins of

IC1 go into the socket and don't get bent underneath or

down the outside of the socket. |

With all parts assembled, check the underside of the

board to make sure the solder joints are good and there

are not shorts or solder bridges. If the

inspection is okay, you can now connect the assembled

board to a battery or power supply.

The input voltage to

the board should be between 6 volts and 14 volts DC.

|

Power Supply

The board can be powered from a

9 volt battery such as a PP3, or a 12 volt battery including

connection to a car electrical system. Alternatively it

can be connected to a suitable DC power supply rated between 6

and 14 volts and able to supply at least 150mA.

In the UK you can buy a suitable power

adapter from Rapid Electronics. You'll also find similar

power adapters available from retail stores and e-Bay.

Rapid

Electronics 5W SWITCH MODE PLUGTOP PSU 9V 550MA

RC Part # 85-2926

If wiring to an alternative

power source (not using the battery terminal clip supplied in

the kit) make sure the polarity of the power supply is correct;

at the PCB the positive supply to the '+' and negative to the

'-' connection points.

User Operation Guide

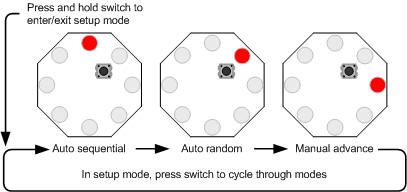

The chaser has three modes of

operation.

- Manual mode will run the

same sequence continually. When the switch is pressed it

will skip to the next sequence in program memory.

- In auto-sequential mode,

the program runs through each sequence in program memory

until it reaches the end of all defined sequences at which

point it restarts from the first one.

- In random mode the program

selects sequences randomly.

When the chaser is running in any

mode, a short press of the switch will make the controller skip

to the next sequence.

To enter setup mode, press and

hold the switch. Once it enters setup mode one of three

LEDs will light indicating the current run mode. A short

press of the switch cycles through the three modes. When the

desired run mode has been selected, press and hold the switch to

exit setup and return to run mode.

The current mode and selected

sequence are automatically saved to the PICs internal

non-volatile EEPROM memory 10 seconds after the last switch

press. When the LED chaser is next powered up it will load

and start running using the saved mode and sequence.

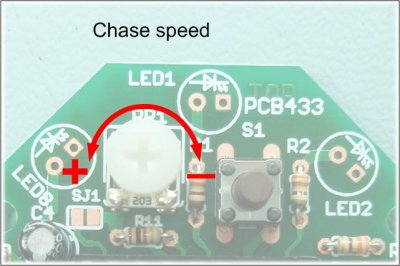

Adjusting the chase speed.

The chaser speed can be

adjusted by rotating PR1 as shown

+ increase the speed

- decrease the speed

Description of Sequence Data

| The data

used to create the sequences is held in a separate

include file. You can add, remove or edit this

data to create your own chaser sequences.

To make the creation of

the data file easier a set of macros have been defined

which are used to create the sequence data. This

is described in the

Sequence data flowchart

(also available

as a JPEG image right)

(also available

as a JPEG image right)

If you download the

source code and look at the file named

pro433_SeqDataUFO.inc you can see the data used in this

project. You might want to edit this file as a

starting point to create some sequences of your own.

Notes:

- In manual mode,

when the repeat count reaches zero it restarts

the same sequence, to advance to the next sequence

press the switch.

- In Random mode it

will select a random sequence number to run. If

the Mirror flag is true for that sequence it will

also randomly choose to mirror the data or not.

- In auto-sequential

mode if the Mirror flag is true it will run the

sequence and then repeat it with the data mirrored.

|

|

Firmware

The PIC supplied in the kit is

pre-programmed with the firmware

below so you don't need to do anything if you bought the kit.

Should you need to reprogram the

supplied PIC with the original code supplied, use the HEX file below.

The HEX file is ready to

program straight into the PIC chip.

The Source code will allow you

to create your own sequences and then reassemble the code to use

them with the Round PWM LED Chaser kit #433K.

Quick guide to

reassembling firmware using MPLAB

If you need a PIC Programmer I

strongly recommend the

Microchip PICKit 2,

this is available from suppliers world wide or direct from

Microchip. It's reasonably cheap to buy and reliable.

Not got a programmer? Buy

a pre-programmed PIC from the On-line store

|

Description |

Filename |

Download link |

| |

|

|

| Source

code for 16F628A |

pro481v301ufo.zip

21/02/2021 |

download

download |

HEX file

ready to program into the PIC.

Use with 16F628A only |

pro481v301ufo.HEX

V3.0.1 21/02/2021 |

download

download

|

This firmware uses the same pro481 v3.0.1 PWM LED Chaser

'engine' code as the 481/483

PWM LED Chaser projects. The HEX file here has been assembled using

different chase sequence data that contains alternative

sequences to suit the circular LED layout of this

project.

This firmware uses the same pro481 v3.0.1 PWM LED Chaser

'engine' code as the 481/483

PWM LED Chaser projects. The HEX file here has been assembled using

different chase sequence data that contains alternative

sequences to suit the circular LED layout of this

project. |

FAQ

Can you or

how can I make it it run

more than 8 LEDs?

This is probably the most

frequent of the frequently asked questions :-)

The project is an 8 LED Chaser

and the firmware was written to work as an 8 LED chaser.

There is no quick and easy

change to make it a 9, 12 or some other number of LED chaser.

If you need a chaser with more LEDs then this project is not

suitable for your needs.

I want to

put more than one LED on each output channel, how can I do this?

Check out the

Power MOSFET PWM LED Chaser projects

(483)

Will it work

with 3mm LEDs?

Yes, 3mm LEDs will work as will

8mm and 10mm LEDs. 3mm LEDs can be mounted on the PCB, 8mm

and 10mm LEDs would need to be connected by flying leads.

Can I use

less than 8 LEDs?

Yes, since the sequences are

user definable you can create sequences that use less than 8

LEDs.

I only want

it to run one sequence, can it do that?

Since the current mode and

selected sequence are saved to NVRAM, it always powers up in the

last mode and running the last sequence. Therefore if you

select manual mode and the sequence required, it will run only

that sequence until you change it.

Do the LEDs

have to be the same colour?

No they don't. If you

want you can mix different coloured LEDs. You can also mix

3mm/5mm/8mm/10mm LEDs if you want too.

Can it run

from a 12volt car battery?

Yes, should work fine from a

car battery. We suggest you include an in-line fuse of

250mA in series with the power lead to the board.

Can you

modify the code to run on a PIC type xyz?

The code has been written to

run on three of the most popular PICs available. If you

want to modify the source code it could be made to run on other

PIC types, however we won't modify the code.

|