This section covers how the

circuit works, but you don't need to understand it to build a

working charger sharing controller, so feel free to skip it.

The circuit is controlled by

IC2, a PIC16F628A microcontroller running firmware written in

MikroC (firmware and compiler can be downloaded free)

There are four single pole

relays on the PCB that connect the input from the battery

charger to each individual output. The software controls

the operation of the relays so that only one relay is active at

any time. When switching from one bike to the next all outputs are switched off for 30

seconds to allow the charger to 'see' the disconnection and

reset itself. Each output is active for

approximately 8 hours and the controller cycles round the

outputs sequentially so all four outputs will connect over a 32

hour period. The controller senses the presence of the

bike battery on each output so unconnected outputs are skipped

e.g. if only two bikes are connected each bike gets an 8 hour

charge every 16 hours. The timings are written into the

controller software, if you want to change them you will need to

edit and recompile the C source code.

The circuit is powered using

the batteries on the connected motorbikes. Diodes D1 to

D4 feed power from each bikes battery to the circuit. The

diodes isolate the bikes batteries from each other and only the bike with

the highest battery terminal voltage actually powers the circuit; this

will normally be the battery currently charging.

The voltage at each of the

four outputs is fed to the microcontroller sense inputs via a

resistor network comprising 10K and 3K3 resistors. This

divides the input voltage by 4.03 so a voltage above

approximately 8 volts at the output will feed 2 volts to the

sense input of the microcontroller IC2. This is seen as a high logic level

by the software and

allows the controller to detect which outputs are actually

connected to a bike.

The 12 volt supply from the

bike battery feeds the relay coils and also to a 5

volt regulator IC1. This regulator IC is an LP2950 micro-power

precision Low Dropout regulator and provides regulated 5 volts to the

microcontroller. The relay coil voltage is a nominal 12V

DC but is rated to 1.5x this which is 18 volts so they are okay

working with typical battery terminal voltages of 12.5 to 14.8

volts.

Capacitor C3 provides

decoupling of the input power. C2 does the same for the 5 volt

output. C4 is required by the voltage regulator IC1 to

maintain a stable output. Capacitor C3 is rated at 25

volts, don't use a lower voltage rated part here.

The five LEDs connect via 560

ohm resistors to the microcontroller. This is quite a high

value but it keeps the LED current around 5mA which helps keep

the overall current consumption of the circuit low.

The ground connection of the

battery charger and all the bikes are connected together on the

PCB. The positive output from the charger is fed to

the common pole of all four relays. The output of each relay feeds one bike.

When the corresponding relay is turned on, the positive output

from the battery charger is connected to the bike and therefore allows

the battery to be charged.

A ULN2003A

Darlington transistor array is used to switch the relays using

four of the seven outputs. Each output of the

ULN2003A incorporates

a diode to provide clamping of the relay coil flyback voltage.

The choice of this IC over discrete components was made to keep

the PCB layout simpler and more compact.

Charging Current and Voltage

Quick digression here.

Although the relays are rated for 10 amp switching, the PCB

traces are only good for about 3 amps. This is more than

adequate for most motorbike chargers, in fact the charger I use only

outputs 800mA. If you heavily tin the PCB tracks with

solder around the relays and terminal blocks you can increase

this to maybe 6 amps. The circuit is designed to work with 12

volt batteries only - it won't work with 6 or 24 volt automotive

electrics.

Power Supply

The board requires a nominal 12 volt

DC supply to operate. With D1-D4 installed the board is

powered from the batteries of the motorbikes attached to the

outputs. The battery with the highest voltage at its

terminals will forward bias one of the diodes, causing it to

conduct and power the controller. The other diodes are

then reverse biased and do not conduct. Typically the bike

under charge will have a higher battery terminal voltage than

the others so the controller doesn't drain the batteries

of the non-charging bikes.

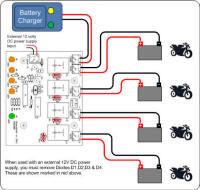

If you don't want it to work

this way you can use an external 12 volt DC power supply

connected to the 'external power input' connector. If you

do this you MUST omit diodes D1-D4. Also ensure the

power supply output does not have a connection to the AC mains

earth.

When using the external power

input terminal the board is protected from a reverse polarity connection by

diode D5.

Each relay requires about 35mA

to operate, the 5 LEDs when all on add another 25mA and the rest

of the circuit uses about 5mA. The heartbeat LED flashes

at 1Hz, and the channel connection LEDs for 100mS every 2.5

seconds, only the active channel LED is on constantly and since

only one relay is active at any time the average current

consumption is typically under 50mA.

Building for less than four

channels

If you don't need four channels

you can omit the LEDs, resistors, relay and diode for an unused

channel. Even if a channel output isn't used you should

fit the 3K3 resistor (R7 through R10) to ensure the

channel sense input is held low and the software treats it as

unused.

External Crystal

The PCB is laid out to allow

the use of an external crystal for the microcontroller's clock

oscillator using XT1/C5/C6. I chose not to use an external

clock and instead use the internal RC oscillator. While

this doesn't give such accurate time delays, for the intended

application 10 minutes error in 12 hours isn't significant.

If you want to use a crystal it needs to be 4Mhz, the load

capacitors should be 15pF and you will need to change the

configuration word when programming the PIC to use external XT

crystal on RA6/RA7 for the clock source.

You can buy all the parts

needed to build this project from most component suppliers world

wide. In the UK you can get everything from Rapid Online and

I've included a parts list with their part numbers below.

All

Rapid parts/descriptions correct at 10 February 2013. You should

check part# and descriptions are correct when ordering in case

I've made a mistake transferring them onto this page.

|

Component |

Description |

Part # |

| R1-5 |

PACK 100 560R 0.25W CF

RESISTOR (Order 1 pack only) |

62-0364 |

| R6,R11-R14 |

PACK 100 10K 0.25W CF

RESISTOR (Order 1 pack only) |

62-0394 |

| R7-R10 |

PACK 100 3K3 0.25W CF

RESISTOR (Order 1 pack only) |

62-0382 |

| C2 |

100N 2.5MM X7R Dielect

Ceramic Capacitor |

11-3442 |

| C3 |

100uF 25 v low imp

Electrolytic capacitor |

11-2922 |

| C4 |

47uF 10v 5mm Micromin

Electro Capacitor |

11-1502 |

| IC1* |

LP2950CZ-5 micropower

regulator |

82-0680 |

| IC2** |

PIC12F628A-I/P |

73-3340 |

| IC3 |

ULN2003A |

82-0618 |

| D1-D5 |

1N4148 75V 200mA

signal diode |

47-3309 |

| LED1-4 |

Kingbright L-53LYD 5mm

Low Current Yellow Diffused LED 2mcd |

55-0856 |

| LED5 |

Kingbright L-53LGD 5mm

Low Current Green Diffused LED 2mcd |

55-0852 |

| |

|

|

| socket for IC2 |

18 Pin 0.3in Turned Pin

Socket |

22-1723 |

| socket for IC3 |

16 Pin 0.3in Turned Pin

Socket |

22-1722 |

| |

|

|

| K1-K4 |

Finder 12V Relay

(Miniature) SPDT 10A 36.11 |

60-4192 |

Terminal block

Qty 6 |

2 Way 16A Black

Interlocking Terminal Block (order 3) |

21-0440 |

Parts List Notes

All the resistors are

supplied in packs of 100

*

If you

can't get hold of the LP2950 you can substitute a 78L05 5-volt

regulator

**

PIC16F628A

will need to be programmed with the HEX file available to

download at the bottom of this web page.

C1 is not used.

C5/C6/XT1 are optional components and not used in this design